Glass-To-Metal-Seals – our essential skill

Glass-to-metal-seals (GTMS) ensure the hermetic fusion of glass and metal components (typically < 1E-8 mbar l/s). This connection is needed to feed the electrical conductors (pins) hermetically sealed and screened from the surrounding ambient environment into the package.

Why glass-to-metal seals are needed and what the advantages are:

Glass-to-metal-seals are always used when the electronics, the ignition powder or other components must be permanently isolated from the surrounding ambient environment without loss of performance. The harsher the surrounding environment, the easier it is to see the advantages of glass-to-metal seals over plastic connections.

Glass-to-metal seal capabilities:

- high temperatures up to 450°C

- frequent temperature cycles from -65°C to 150°C

- high humidity and humidity changes

- aggressive media such as oil, fuel, saltwater, etc.

- high pressure load up to 2000 bar

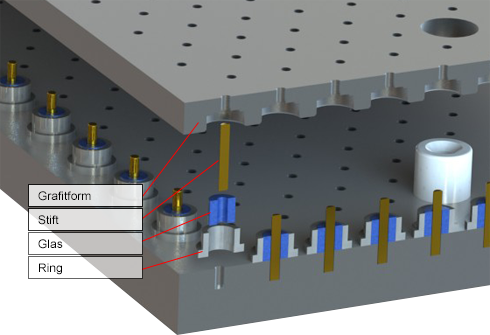

A glass-to-metal seal typically consists of a metal housing, a molded glass-preform and one or several inner conductors. These components are melted in an inert gas atmosphere to form a hermetic seal in a special thermal process at approximately 1000°C.

As a long-standing, globally operating company Electrovac Hermetic Packages is one of the leading developers and manufacturers of glass-to-metal seals.

Typically, glass-to-metal seals are divided into matched and compression seals.

The components used (ring, glass and pin) have approximately the same thermal expansion coefficients. A hermetically sealed connection between the glass and the metals is achieved via oxide layers.

Advantages:

- high temperature resistance up to 450°C

- low thermal expansion

The exterior metal part, typically steel or stainless steel, has a considerably higher thermal expansion coefficient than the glass and the inner conductor. The hermetically sealed connection is achieved through compression.

Advantages:

> high mechanical strength

> low material cost

Typically, the glass-to-metal seals are plated before and/or after the melting process. Depending on customer requirements and the further processing method, the metal parts are nickel, tin, silver or gold plated in our electroplating facility.

You will find additional information and details in our design rules which are available upon request.